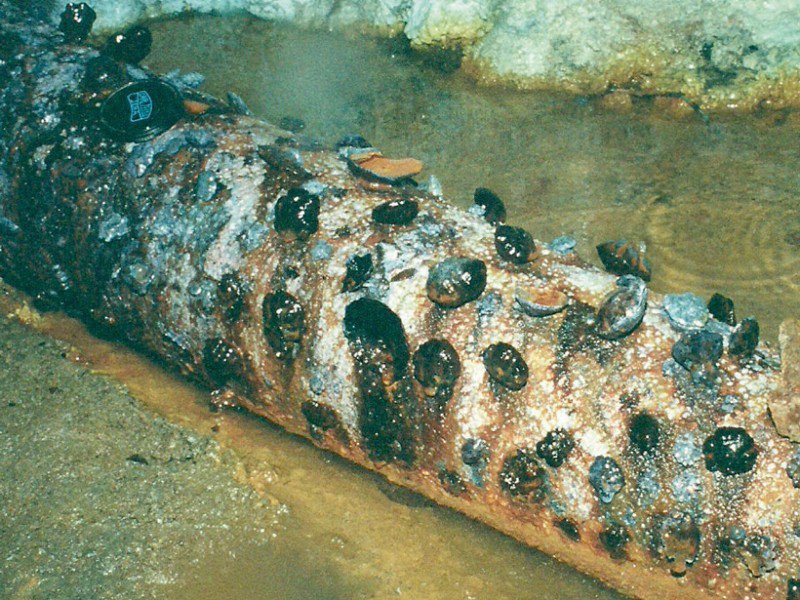

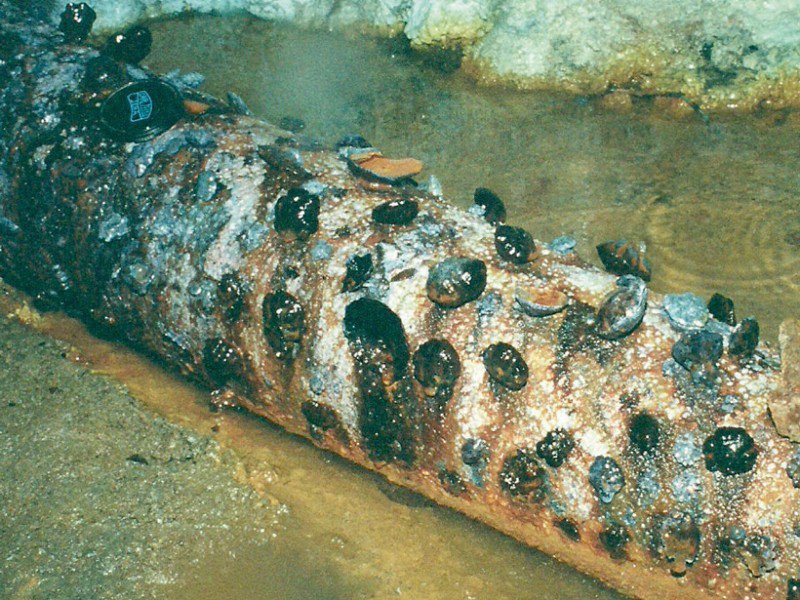

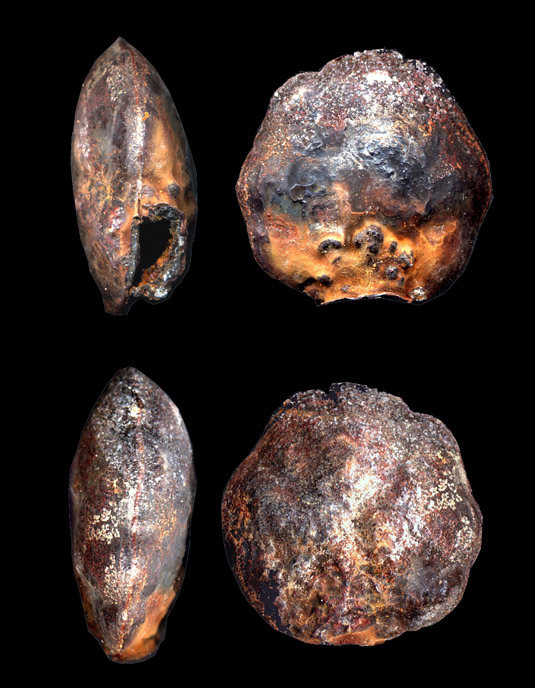

“High in the Pyrenees Mountains,” we read, “deep in abandoned mines, scientists discovered peculiar black shells that seem to crop up of their own accord on metal surfaces.”

[Image: Metal shells growing in the darkness of abandoned mines; photo by Joan Santamaría, via Eos].

[Image: Metal shells growing in the darkness of abandoned mines; photo by Joan Santamaría, via Eos].

No, this is not a deleted scene from Jeff VanderMeer’s Southern Reach trilogy; it’s from research published in the Journal of Geophysical Research: Biogeosciences, recently reported by Eos.

It turns out that, under certain conditions, subterranean microbes can leave behind metallic deposits “as part of their natural metabolism.” Abandoned mines are apparently something of an ideal environment for this to occur within, resulting in “a rapid biomineralization process that sprouts iron-rich shells from the surface of steel structures.”

These then build up into reef-like deposits through a process analogous to 3D-printing: “Electron microscopy revealed small-scale, fiber-like crystals arranged into lines growing outward from the steel surface. The shells appear to be formed layer by layer, with crystal size and composition varying across layers.”

There are many, many interesting things to highlight here, which include but are not limited to:

Slow Printing

We could literalize the analogy used above by exploring how a controlled or guided version of this exact same process could be used as a new form of biological 3D-printing.

To put this another way, there is already a slow food movement—why not a slow printing one, as well?

Similar to the project John Becker and I explored a while back, using genetically-modified bees as living printheads, damp, metal-rich environments—microbial ovens, so to speak—could be constructed as facsimile mines inside of which particular strains of microbes and fungi would then be cultivated.

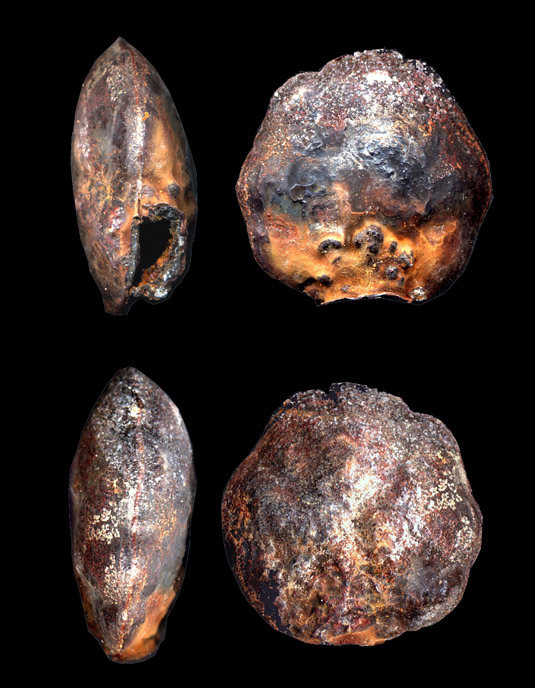

Geometric molds would be introduced as “seed-forms” to be depositionally copied by the microbes. Rather than creating the abstract, clamshell-like lumps seen in the below photograph, the microbes would be steered into particular shapes and patterns, resulting in discrete, recognizable objects.

Boom: a living 3D-printer, or a room of specially cultivated humidity and darkness out of which strange replicant tools and objects could be extracted every few years. At the very least, it would make a compelling art project—an object-reef sprouting with microbial facsimiles.

[Image: Metal shells growing in the darkness of abandoned mines; photo by Nieves López-Martínez, via Eos].

[Image: Metal shells growing in the darkness of abandoned mines; photo by Nieves López-Martínez, via Eos].

Dankness Instrumentalized

Historian David Gissen has written interestingly about the idea of “dankness” in architecture.

In an article for Domus back in 2010, Gissen explained that “dankness”—or “underground humidity,” in his words, a thick atmosphere of mold, rot, and stagnation usually found inside closed, subterranean spaces—was even once posited by architectural historian Marc-Antoine Laugier as a primal catalyst for first inspiring human beings to build cleaner, better ventilated structures—that is, architecture itself, in a kind of long-term retreat from the troglodyte lifestyle of settling in caves.

Dankness, to wildly over-simply this argument, so horrified our cave-dwelling ancestors that they invented what we now call architecture—and a long chain of hygienic improvements in managing the indoor atmospheric quality of these artificial environments eventually led us to modernism.

But dankness has its uses. “While modernists generally held dankness in suspect,” Gissen writes, “a few held a certain type of affection for this atmosphere, if only because it was an object of intense scrutiny. The earliest modernist rapprochements with dankness saw it as the cradle of a mythical atmosphere, an atmosphere that preceded modernity.” The “atmospheric depths of the cellar,” Gissen then suggests, might ironically be a sign of architectural developments yet to come:

Today, in the name of environmentalism, architects are digging into the earth in an effort to release its particular climatic qualities. Passive ventilation schemes often involve underground constructions such as “labyrinths” or “thermosiphons” that release the earth’s cool and wet air. The earth that architects reach into is one that has been so technified and rationalized, so measured and considered, that it barely contains mythical or uncanny aspects. However, this return to the earth’s substrate enables other possibilities.

In any case, I am not only quoting this essay because it is interesting and deserves wider discussion; I am also quoting all this in order to suggest that dankness could also be instrumentalized, or tapped as a kind of readymade industrial process, an already available microbial atmosphere wherein metal-depositing metabolic processes pulsing away in the dankest understructures of the world could be transformed into 3D-printing facilities.

The slow printheads for long-term object replication, mentioned above, would be fueled by and dependent upon Gissen’s spaces of subterranean humidity.

Heavy Metal Compost

If it is too difficult, too unrealistic, or simply too uselessly speculative to consider the possibility of 3D-printing with microbes, you could simply eliminate the notion that this is meant to produce recognizable object-forms, and use the same process instead as a new kind of compost heap.

Similar to throwing your old banana peels, coffee grounds, apple cores, and avocado skins into a backyard compost pile, you could throw metallic waste into a Gissen Hole™ and wait for genetically-modified microbes such as these to slowly but relentlessly break it all down, leaving behind weird, clamshell-like structures of purified metal in their wake.

Cropping teams would then climb down into this subterranean recycling center—or open an airlock and step inside some sort of controlled-atmosphere facility tucked away on the industrial outskirts of town—to harvest these easily commodified lumps of metal. It’d be like foraging for mushrooms or picking strawberries.

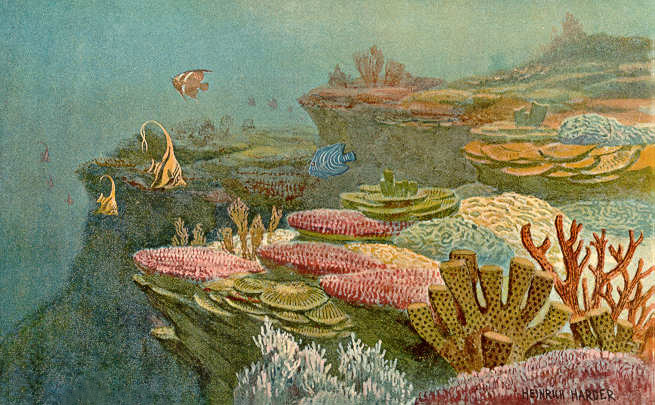

[Image: An “ancient coral reef,” illustrated by Heinrich Harder].

[Image: An “ancient coral reef,” illustrated by Heinrich Harder].

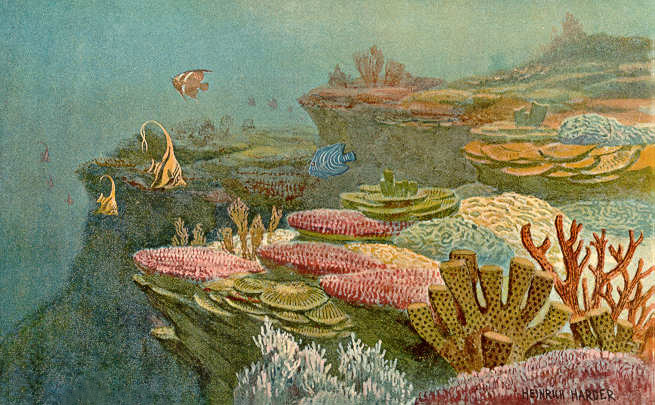

The Coming Super-Reef

Finally, this also seems to suggest at least one fate awaiting the world of human construction long after humans themselves have disappeared.

Basements in the ruined cores of today’s cities will bloom in the darkness with ever-expanding metallic reefs, as the steel frames of skyscrapers and the collapsed machinery of the modern world become source material—industrial soil—for future metal-eating microbes.

Quietly, endlessly, wonderfully, the planet-spanning dankness of unmaintained subterranean infrastructure—in the depths of Shanghai, London, New York, Moscow—humidly accumulates these strange metallic shells. Reefs larger than anything alive today form, crystallized from the remains of our cities.

A hundred million years go by, and our towers are reduced to bizarre agglomerations of metal—then another hundred million years and they’ve stopped growing, now hidden beneath hundreds of meters of soil or flooded by unpredictable shifts of sea level.

Clouds of super-fish unrecognizable to today’s science swim through the grotesque arches and coils of what used to be banks and highways, apartment blocks and automobiles, monstrous and oyster-like shells whose indirect human origins no future paleontologist could realistically deduce.

[Image: Plankton via the Seattle Aquarium.]

[Image: Plankton via the Seattle Aquarium.] [Image: From a project called “

[Image: From a project called “ [Image: From “

[Image: From “ [Image: From “

[Image: From “

[Images: From “

[Images: From “ [Image: From “

[Image: From “ [Image: From “

[Image: From “ [Image: From “

[Image: From “ [Image: Ice formwork for casting concrete, developed by

[Image: Ice formwork for casting concrete, developed by  [Image: Ice formwork for casting concrete, developed by

[Image: Ice formwork for casting concrete, developed by  [Image: Ice formwork for casting concrete, developed by

[Image: Ice formwork for casting concrete, developed by  [Image: “The Sphere” by Oliver Tessman, Mark Fahlbusch, Klaus Bollinger, and Manfred Grohmann].

[Image: “The Sphere” by Oliver Tessman, Mark Fahlbusch, Klaus Bollinger, and Manfred Grohmann]. [Image: Matter Design’s La Voûte de LeFevre, Banvard Gallery (2012)].

[Image: Matter Design’s La Voûte de LeFevre, Banvard Gallery (2012)]. [Image: Greg Lynn’s “Embryological House,” Venice Biennale (2002)].

[Image: Greg Lynn’s “Embryological House,” Venice Biennale (2002)]. [Image: “Custom forming tool mounted on the six-axis robotic arm,” via

[Image: “Custom forming tool mounted on the six-axis robotic arm,” via  [Image: Neri Oxman’s otherwise unrelated “

[Image: Neri Oxman’s otherwise unrelated “

[Image: Unrelated image of incredible floral shapes 3D-printed by

[Image: Unrelated image of incredible floral shapes 3D-printed by  [Image: An also unrelated project called “

[Image: An also unrelated project called “ [Image: “

[Image: “ [Image: Spot the model; from Jessica Rosenkrantz’s

[Image: Spot the model; from Jessica Rosenkrantz’s  [Image: “

[Image: “ [Image: “

[Image: “ [Image: “

[Image: “

[Image: Micromotors at work, via

[Image: Micromotors at work, via  [Image: A Maltese limestone quarry, via

[Image: A Maltese limestone quarry, via

[Image: Metal shells growing in the darkness of abandoned mines; photo by

[Image: Metal shells growing in the darkness of abandoned mines; photo by  [Image: Metal shells growing in the darkness of abandoned mines; photo by

[Image: Metal shells growing in the darkness of abandoned mines; photo by  [Image: An “

[Image: An “

Last week, over at the

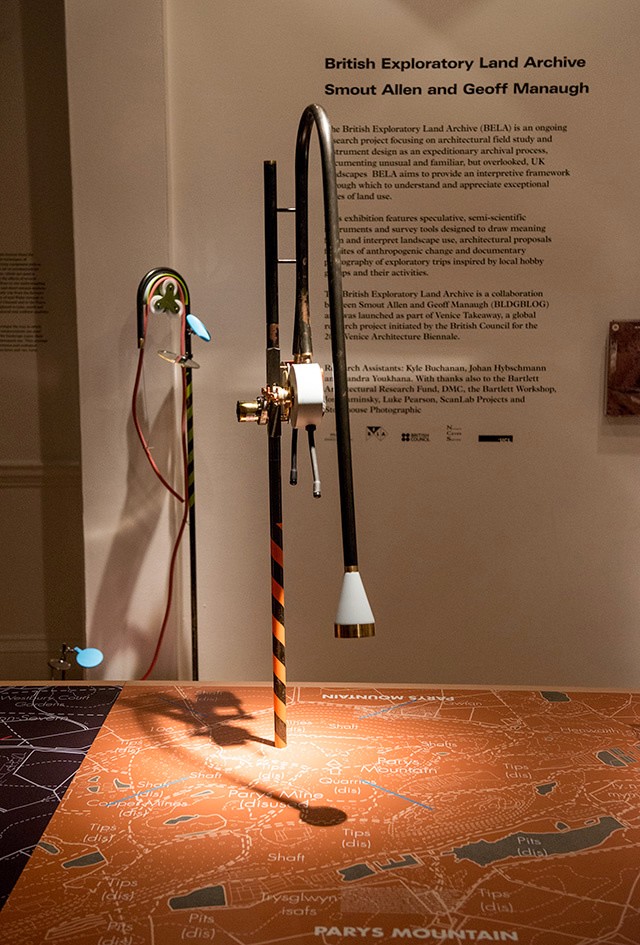

Last week, over at the  Although I was unfortunately not able to be in London to attend the opening party, I was absolutely over the moon to get all these photographs, taken by

Although I was unfortunately not able to be in London to attend the opening party, I was absolutely over the moon to get all these photographs, taken by

The work on display ranged from cast models of underground sand mines in Nottingham, based on laser-scanning data donated by the

The work on display ranged from cast models of underground sand mines in Nottingham, based on laser-scanning data donated by the  From the bizarre environmental-sensing instruments first seen back at the

From the bizarre environmental-sensing instruments first seen back at the

I should quickly add that the exhibition is, by far and away, the work of Smout Allen, who burned candles at every end to get this all put together; despite being involved with the project, and working with the ideas all along, since

I should quickly add that the exhibition is, by far and away, the work of Smout Allen, who burned candles at every end to get this all put together; despite being involved with the project, and working with the ideas all along, since  In any case, a brief note on the collaboration with

In any case, a brief note on the collaboration with  This would be an energy-storage landscape—in effect, a giant, island-sized, semi-subterranean field of batteries—where excess electrical power generated by the gargantuan offshore field of wind turbines called the

This would be an energy-storage landscape—in effect, a giant, island-sized, semi-subterranean field of batteries—where excess electrical power generated by the gargantuan offshore field of wind turbines called the

This island of half-buried spinning machines included tiny motor parts and models based on Williams’ own

This island of half-buried spinning machines included tiny motor parts and models based on Williams’ own

It was these little parts and models that were 3D-printed in alumide—a mix of nylon and aluminum dust—for us by engineers at Williams.

It was these little parts and models that were 3D-printed in alumide—a mix of nylon and aluminum dust—for us by engineers at Williams.  The very idea of a 3D-printed energy storage landscape on the British coast, disguised as an island, whirring inside with a garden of flywheels, makes my head spin, and a part of me would actually very much love to pursue feasibility studies to see if such a thing could potentially even be constructed someday: a back-up generator for the entire British electrical grid, saving up power from the

The very idea of a 3D-printed energy storage landscape on the British coast, disguised as an island, whirring inside with a garden of flywheels, makes my head spin, and a part of me would actually very much love to pursue feasibility studies to see if such a thing could potentially even be constructed someday: a back-up generator for the entire British electrical grid, saving up power from the  Finally, thanks not only to Williams, but to the

Finally, thanks not only to Williams, but to the

The exhibition is

The exhibition is

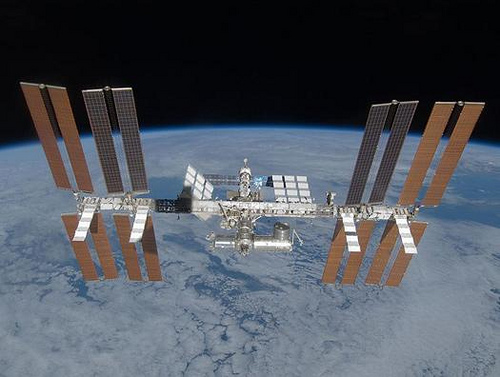

[Image: The International Space Station, courtesy of

[Image: The International Space Station, courtesy of  [Image: Mars rover and its gadgets, courtesy of

[Image: Mars rover and its gadgets, courtesy of  [Image: “

[Image: “ [Image:

[Image:  [Images: The Rosslyn Chapel hives; photos courtesy of the

[Images: The Rosslyn Chapel hives; photos courtesy of the